High-Pressure "HP" GRE Fittings

Our HP Glass Reinforced Epoxy (GRE) fittings are meticulously engineered for the demanding oil and gas industry, offering exceptional durability, corrosion resistance, and reliable performance under high-temperature and HP conditions. These fittings are built to withstand harsh environments, providing leak-proof connections for critical applications like offshore platforms, oilfield infrastructure, and petrochemical transport systems.

Designed to endure temperatures up to 100°C, the advanced curing system enhances the fittings’ ability to handle the rigorous demands of oil and gas fluid transport. These fittings offer long-lasting performance, ensuring reliability and safety in the most extreme conditions. Engineered to meet the toughest requirements of the oil and gas sector, they provide robust, efficient, and leak-resistant solutions for transporting fluids in HP environments.

Available Fittings

Elbows – Used to change the direction of pipeline systems, suitable for flexible routing in confined spaces or complex installations.

Tees – Essential for branching or connecting pipelines at specific angles, ensuring seamless integration within oil & gas networks.

Reducers – Facilitate size transitions between different pipeline diameters, ensuring smooth flow and reducing flow resistance.

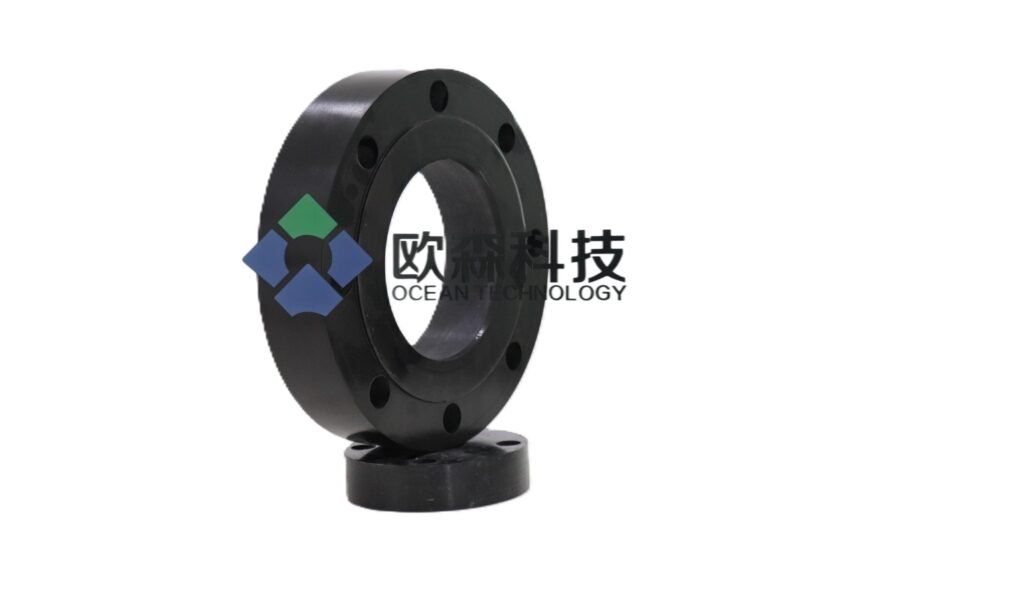

Flanged Fittings – Provide secure connections between pipes and other components, ensuring leak-proof seals under HP conditions.

- Couplings – Used for joining two sections of pipe together.

- Joint Accessories – Include tools, gaskets, bolts, nuts, seals, and lubricants to ensure secure, leak-proof connections, enhancing the overall reliability and performance of pipeline systems.

Key Features

Handles Pressures Up to 250 Bar – Designed to withstand the extreme pressure conditions common in oil & gas applications, our fittings ensure safety and reliability in HP systems.

Superior Sealing Performance – Threaded joints and advanced sealing systems provide reliable, leak-proof connections, maintaining the integrity of the pipeline even in HP environments.

Corrosion & Chemical Resistance – Manufactured using non-corrosive materials and high chemical resistance, these fittings are built to endure the harshest oilfield environments, including offshore and petrochemical applications, ensuring long-term durability.

Lightweight & Easy to Handle – Despite their strength, our fittings are lightweight, simplifying installation and reducing transportation costs, especially in remote oil and gas locations, minimizing downtime.

Minimal Maintenance – Designed for exceptional durability, our fittings’ corrosion resistance minimizes the need for frequent repairs, resulting in significant cost savings over time.

Global Compliance – Manufactured to international standards, ensuring superior performance and compatibility with oil and gas industry regulations, minimizing risk and ensuring reliability in demanding environments.

Customisable for Oil & Gas Applications – Available in a range of sizes, pressure ratings, and materials, our HP GRE fittings can be tailored to meet the specific demands of your oil & gas operations, offering optimal performance for HP, chemical, and corrosive fluid transport systems.

Applications

✔ Offshore Oil & Gas Platforms – Reliable, durable, and resistant to marine conditions, these fittings are perfect for offshore applications where corrosion is a significant concern.

✔ Onshore Oil & Gas Pipelines – Used for HP fluid transport in onshore exploration and production sites.

✔ Crude Oil & Natural Gas Transport – Ensure smooth and efficient fluid transport through gathering lines, tank connections, and processing facilities.

✔ Petrochemical & Refining – Ideal for petrochemical transport systems, including high-temperature and HP environments within refining processes.

✔ Oil & Gas Distribution Systems – Critical for transporting oil, natural gas, and chemicals safely and efficiently across large distances or confined spaces.

Premium Materials & Quality Control

Our HP GRE fittings are manufactured using premium epoxy resins and PPG fiberglass, sourced from trusted suppliers like DOW and PPG. These fittings are designed to provide superior strength, HP durability, and exceptional corrosion resistance, ensuring reliable performance under extreme conditions, including high-temperatures and exposure to aggressive oil and gas fluids. They are coated with an Amine-Cured Epoxy System, providing enhanced protection against chemical attack and wear, ensuring long-term reliability in aggressive oil and gas environments.

Each fitting is rigorously tested, including hydrostatic pressure testing, and manufactured in compliance with ISO 9001 (Quality Management Systems), API 15LR (Oil and Gas Pipeline Systems), API 15HR (High-Pressure Systems), ISO 14692 (Petroleum and Natural Gas Industry Standards), and ASTM F1173 (Jet Fire Resistance), ensuring top-tier quality, reliability, and durability in demanding oil and gas environments.

Smart Product Selection

Our Step-by-Step Product Selector tool makes choosing the right GRE fitting easy. Based on your specific needs, you can select the ideal fitting by considering:

Pressure Rating: Low, Medium, High

Temperature Range: (<65°C, 65°C–93°C, >93°C)

Application Type: Oil & Gas (including offshore platforms, gathering lines, chemical transport and power generation facilities)

The product selector offers real-time recommendations, giving you direct access to product specifications and downloadable reports to facilitate informed decision-making.

Specifications Table

Feature | HP Oil & Gas GRE Fittings |

Pressure Rating | 3.5 MPa – 25 MPa ( ~ 35 – 250 bar ) |

Diameter Range | DN 38mm–200mm |

Temperature Resistance | Up to 100°C |

Applications | Oil & Gas, Power Plants |

Standards | API 15LR, API 15HR, ISO 14692, ISO 9001, ASTM F1173 |