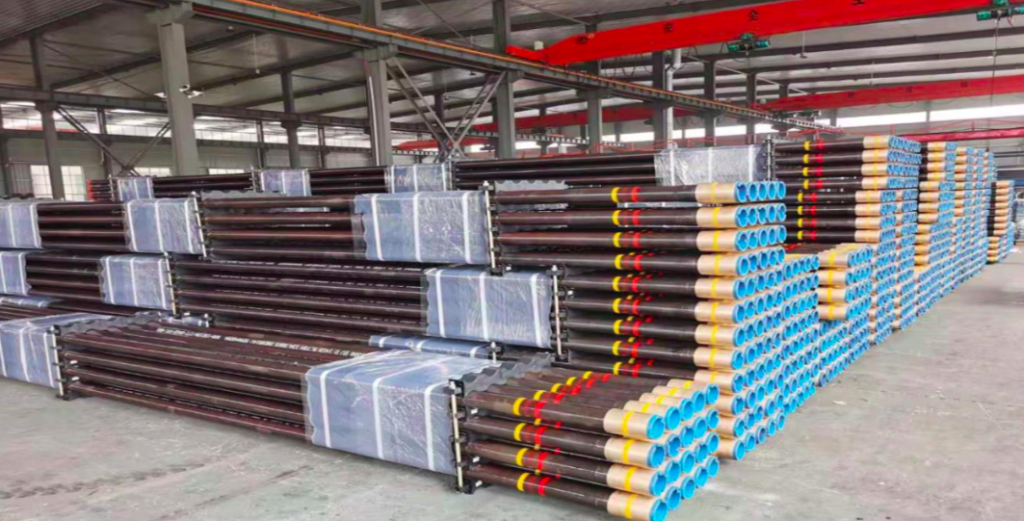

Certified Carbon Steel Pipes & Fittings

Carbon steel pipes and fittings engineered for industrial, oil & gas, and water applications, providing high strength, durability, and reliable performance under a wide range of pressures and temperatures.

Key Features

- Premium carbon steel grades

- High mechanical strength (For industrial and oilfield operations)

- Optional GRE lining for corrosion protection

- Maintenance-free in non-corrosive environments

- Tubing, casing, structural pipes

- Precision threaded, cut, and machined

- Certified ISO 9001, API SPEC Q1, API SPEC 5CT, GOST

- Cost-effective and customisable

Tubing & Casing

Casing: Large-diameter carbon steel pipe that stabilizes the wellbore and protects underground formations.

Tubing: Smaller-diameter carbon steel pipe inside casing, transporting oil, gas, or water to the surface.

Fittings & Accessories

- Elbows (45°, 90°, Long Radius, Short Radius)

- Tees (Equal / Reducing)

Reducers (Concentric / Eccentric)

Caps & Plugs

Flanges (Weld-Neck, Slip-On, Blind, Threaded, Socket-Weld)

Couplings

Crossovers (size and thread-type transitions)

Premium Connections (high-integrity threaded connectors for demanding applications)

Custom CNC-Machined Components

Applications

✔ Onshore Oil & Gas Pipelines

✔ Crude Oil & Natural Gas Transport (pipeline networks, tank connections, and processing facilities)

✔ Petrochemical & Refining Applications

✔ Industrial & Infrastructure Projects – (Mining, heavy industry, and structural piping)

✔ Water & Steam Distribution Systems

✔ Construction & Structural Piping

✔ Agricultural & Irrigation Systems

✔ Power Generation Facilities

Certifications

API SPEC Q1 Quality Management System

ISO 9001 Certified

API SPEC 5CT Product Certification

GOST Certification (Russian Federation)

ES-2 Premium Connection passed ISO 13679 Level 4 sealing test

Advanced Manufacturing & Equipment

Precision Manufacturing: CNC machining, threading, and precision end-finishing for consistent quality

Cut-to-Length Services: Custom lengths to meet project specifications

Coating & Painting: Automated lines for accurate finishing and improved durability

Material Options: Standard carbon steel and corrosion-resistant grades for industrial, oilfield, construction, and mining applications

High-Capacity Production: Tubing & casing lines with advanced DMG and Doosan equipment

Quality Assurance: Full non-destructive testing (NDT) for chemical, mechanical, and dimensional verification

Reliable Performance: Designed for demanding industrial, oilfield, and structural projects

Full Project Support & Quality Assurance

Every product undergoes non-destructive testing (NDT), mechanical, and dimensional verification to guarantee performance and safety. We also provide full documentation, including MTCs, test reports, and compliance certificates, backed by engineering and supply support for fast, reliable project delivery.

Specifications Table

Feature | Carbon Steel Pipes |

Pressure Rating | Low to medium pressure, depending on steel grade and wall thickness |

Diameter Range | 1.66” – 20” (42mm – 508mm) |

Temperature Resistance | Suitable for typical industrial and oilfield operations |

Applications | Onshore Pipelines, Crude Oil & Natural Gas Transport, Petrochemical/Refining Process Lines, Industrial piping, Structural projects, Water & Steam distribution, Power Generation Facilities |

Standards | API SPEC Q1, ISO 9001, API SPEC 5CT, GOST (Russian Federation) |