Certifications & Approvals

Testing & Laboratory Capabilities | QA/QC

At Petronich Pipe Solutions, quality is engineered into every pipe system we deliver. Our testing and laboratory facilities support strict QA/QC inspection and full material traceability for GRE /GRP, and carbon steel products.

From raw material inspection to final dispatch, every pipe is tested, documented, and certified in accordance with API, ABS, and CCS standards, ensuring reliable performance, regulatory compliance, and reduced operational risk for critical pipeline applications.

Select a product category below to view detailed QA/QC information...

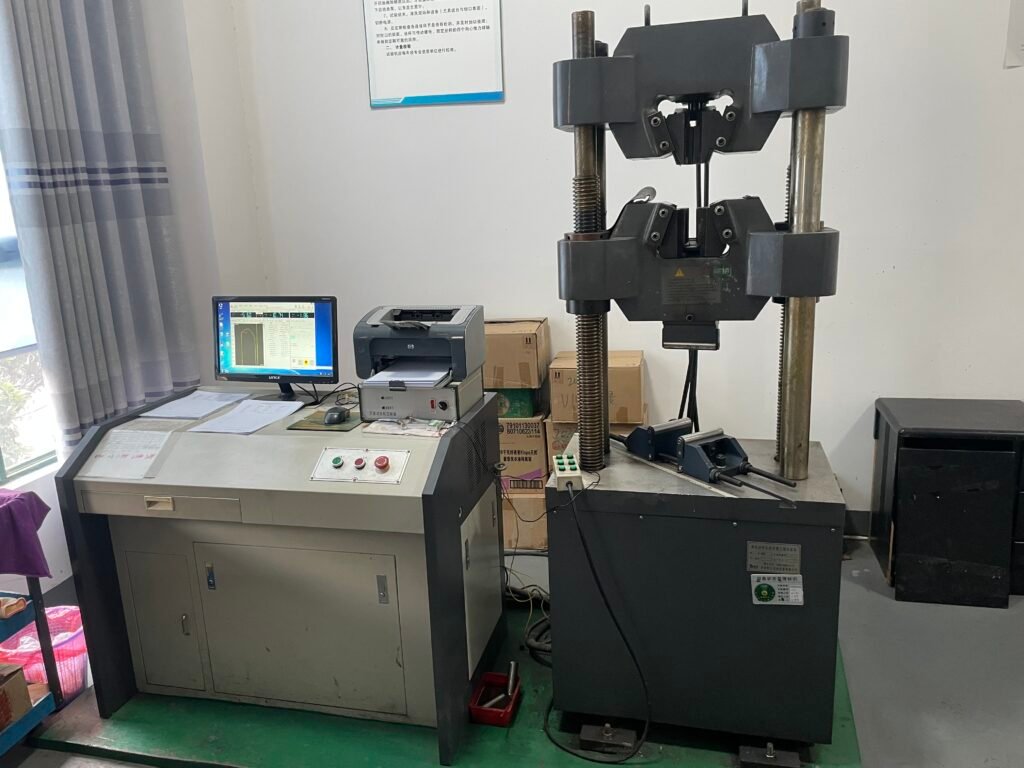

GRE & GRP Pipe Testing and Laboratory Facilities

Our GRE and GRP piping systems are validated through advanced fiberglass testing protocols supported by Shandong Ocean Pipe Technology.

QA/QC requirements are product- and manufacturer-specific. Please contact Petronich Pipe Solutions for project-specific verification.

What quality assurance (QA) and quality control (QC) processes does Petronich Pipe Solutions follow?

At Petronich Pipe Solutions, every pipe undergoes rigorous QA/QC processes to ensure reliability and safety. Our procedures include full traceability from raw materials to final delivery, strict compliance with API, ABS, CCS, and project-specific standards, and documented batch inspections. We combine advanced laboratory testing with systematic manufacturing controls to guarantee consistent high-quality performance for GRE, GRP, and Carbon Steel piping systems.

How are GRE and GRP pipes tested for performance and durability?

GRE and GRP pipes are tested using advanced pressure, tensile, and thermal stability evaluations. Our dedicated fiberglass performance lab, supported by Shandong Ocean Pipe Technology, ensures each pipe meets rigorous standards for strength, flexibility, and long-term reliability. Every batch undergoes real-time monitoring and comprehensive laboratory checks to comply with international standards and provide confidence in critical industrial and offshore applications.

What Non-Destructive Testing (NDT) is performed on Carbon Steel pipes?

Carbon Steel pipes undergo full Non-Destructive Testing (NDT), including Fluorescent Magnetic Particle Inspection (FMPI), ultrasonic testing, and visual inspections. These methods detect surface and near-surface defects, verify mechanical integrity, and ensure compliance with API 5CT and project-specific requirements. Our in-house NDT capabilities, supported by Jiangsu Taishun Energy Technology Development Co., Ltd., allow immediate verification, reducing risk and ensuring consistent, high-performance steel pipes for demanding pipeline applications.

How does Petronich ensure full traceability of its products?

Traceability is a cornerstone of our quality system. Every pipe is fully documented with Material Test Certificates (MTCs), batch records, and certified product release forms. From steelmaking to manufacturing, inspection, and final delivery, our QA/QC protocols ensure all materials and processes are recorded, enabling clients, auditors, and inspectors to verify compliance at any stage.

Why should clients choose Petronich Pipe Solutions for high-performance piping systems?

Clients choose Petronich Pipe Solutions for our combination of advanced testing, rigorous QA/QC, and full traceability. Our state-of-the-art laboratories, real-time monitoring systems, and documented quality procedures ensure GRE, GRP, and Carbon Steel pipes perform reliably under demanding conditions. By maintaining strict standards and robust process controls, we reduce operational risk, guarantee compliance with international codes, and provide clients confidence in every installation.